News

I have begun a Substack site. Take a look by clicking here.

You can take a look first and then sign up to receive the emailed newsletters.

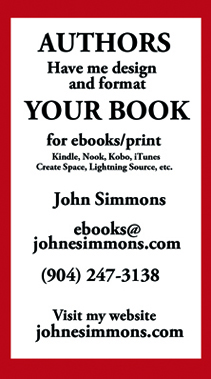

Welcome to the site. It features my Fine Art Photography, Feature Writing on the Arts, and information on book design, writing and promotion.

I am the author of the Skunk Moses, Jamboree Jones and Leland Blake mystery series. Links to the individual sites are in the sidebar to the right.