I spent several days carefully inspecting the operating mechanism and being sure that everything else seemed to work. Then I went to work with penetrating oil – PB Blaster that I use on my cars. I put the typewriter outside on the porch and sprayed it thoroughly for two days. After that treatment, I was able to move some of the typebars with my finger, but the 2, q, a, and z typebars were still firmly stuck. After again giving it a through inspection, pushing the keys, pulling the typebars, and thoroughly understanding how the mechanism was supposed to work, I sprayed again at the points that looked stuck.

After another two days of soaking, the typebars were still stuck, so I resorted to force. I grabbed the typebars with needle nosed pliers in about the center of the parts shown in the photo below. I had to pull hard, but pulled them free. I sprayed more penetrating oil into the slots that the typebars travel in, and worked them back and forth by hand. They eventually freed, and I was able to raise the typebars to the working position.

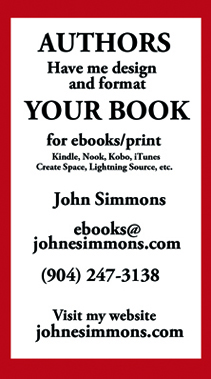

The lever on the right side raises and lowers the typebars.

I rolled a sheet of paper into the machine and tried it out. Everything works beautifully – I’m amazed at how solid a machine this is. It’s much more firm than the later small machines, and seems as though it will be practical to type on. Other problems I notice are flattened rollers that will need to be replaced, and a lot of dirt. I doubt that it will be possible to match the paint, so I’ll probably leave the chips as they are.

Update – The rollers were replaced with tubing from an automotive store. The dirt inside was easily removed by spraying liberally with electric motor cleaner from the hardware store.

- Remington portable with typebars down

- Remington typebars

- Typebar lever

- Remington portable with typebars raised